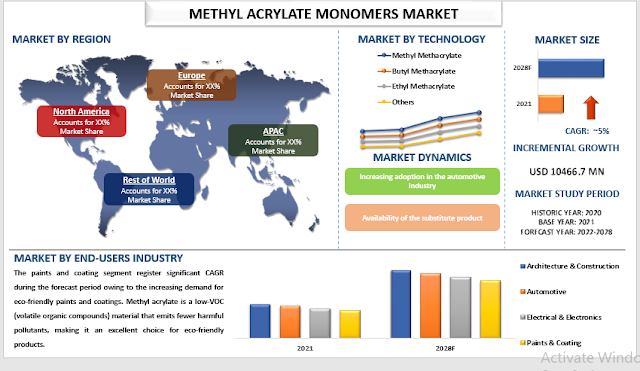

The Methyl Acrylate Monomers Market was valued at USD 10,466.7 million in 2021 & is expected to grow at a CAGR of 5.0% from 2022-2028. owing to the increasing utilization in many polymerization processes due to their relatively low viscosity and low glass transition temperature, which makes them suitable for use in coatings, adhesives, and other applications that require flexibility and toughness.

Methyl acrylate is a colorless, flammable liquid with a sharp, fruity odor. It is an organic compound that is used primarily as a monomer in the production of various polymers, including acrylic polymers, resins, and copolymers.

Methyl acrylate monomers have gained significant adoption in the chemical industry due to their unique chemical properties, wide range of end-use applications, and growing focus on sustainability. Methyl acrylate is a colorless, flammable liquid with a sharp, fruity odor. It is an organic compound that is used primarily as a monomer in the production of various polymers, including acrylic polymers, resins, and copolymers.

Download Exclusive PDF Preview - https://univdatos.com/get-a-free-sample-form-php/?product_id=38110

The adoption of methyl acrylate monomers is driven by several factors. First, its unique chemical properties make it a versatile material for various applications. For instance, its ability to polymerize with other monomers such as butadiene, styrene, and vinyl acetate enables the production of a wide range of copolymers with unique properties such as elasticity, adhesion, and impact resistance. Additionally, the polymerization of methyl acrylate can be initiated by heat, light, or chemicals, making it a flexible material for various industrial processes.

Secondly, the increasing demand for various end-use applications such as coatings, adhesives, and textiles has also driven the adoption of methyl acrylate monomers. Acrylic coatings, for example, are widely used in automotive, construction, and industrial applications due to their superior durability, weather resistance, and aesthetic appeal. Similarly, acrylic adhesives are preferred in various industries due to their high bonding strength, flexibility, and resistance to water and chemicals. The versatility of methyl acrylate makes it an ideal material for such applications.

Thirdly, the growing focus on sustainability has also contributed to the adoption of methyl acrylate monomers. The production of acrylic polymers from methyl acrylate monomers is less energy-intensive and generates less waste compared to traditional materials such as PVC. Additionally, the use of acrylic coatings and adhesives can extend the lifespan of various products, reducing the need for frequent replacements and minimizing waste.

In North America, the adoption of methyl acrylate monomers has been driven by the growth in the construction and automotive industries. These industries have a high demand for products such as adhesives, coatings, and sealants that are made using methyl acrylate monomers. The increasing demand for lightweight vehicles has also boosted the demand for methyl acrylate-based polymers, which are used in the production of lightweight components.

For More Informative Information, Please Visit US – https://univdatos.com/report/methyl-acrylate-monomers-market/

In Asia Pacific, the adoption of methyl acrylate monomers has been driven by the growth in the construction industry. Rapid urbanization and industrialization have led to an increase in the construction of residential and commercial buildings, which has boosted the demand for adhesives, coatings, and sealants that are made using methyl acrylate monomers. The increasing demand for automotive vehicles in countries such as China and India have also boosted the demand for methyl acrylate-based polymers.

In Europe, the adoption of methyl acrylate monomers has been driven by the growth in the packaging industry. Methyl acrylate-based polymers are widely used in the production of packaging materials, including food packaging and medical packaging. The increasing demand for sustainable packaging materials has also boosted the demand for methyl acrylate-based polymers, which are recyclable and can be used to produce biodegradable materials.

Conclusion:

The adoption of methyl acrylate monomers and drivers outlook varies in different regions depending on various factors such as economic conditions, industrialization level, and demand for specific products. The growth of different industries such as construction, packaging, automotive, and oil and gas has been the main driver of the adoption of methyl acrylate monomers in different regions. As the demand for sustainable and environmentally friendly products increases, the use of methyl acrylate-based polymers is expected to grow in different regions.

Comments